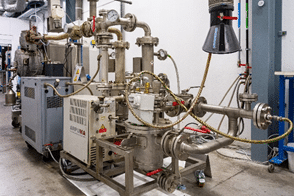

- Semi-continuous custom reactor (5 or 20 L) with solids addition (1 kg/h)

and distillation units for pyrolysis, catalytic cracking, waste treatments, biomass conversion, powder drying, etc. - Commercial meso/microreactors for continuous flow chemistry

- Custom reactors for continuous flow chemistry: heterogeneous catalysis (e.g., VOC oxidation), biomass conversion, organic and inorganic chemistry

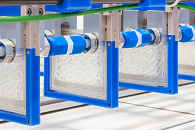

- Custom flow reactors for continuous treatment of slurries (design and engineering according to project needs)

- Membrane separator for continuous liquid-liquid and liquid-gas separation

Chemistry & Industrial Processes Technological Platform

Lab and pilot-scale reactor systems

High pressure reactors and equipment for chemical synthesis

- Stainless steel autoclaves 316L or Hastelloy®C276 (75 to 1000mL) for high-pressures and high temperatures treatments (up to 500 °C and 600 bar) for application in catalysis, hydrothermal synthesis, waste treatments (solvolysis), etc.

- Microwave reactor (0.5 to 20 mL vessels) (up to 250°C and 20 bar)

- Spray Dryer (drying, synthesis, encapsulation)

Characterisation

- NMR (access), GC-FID, GC-MS, GC-TCD, HPLC, IR, Raman, UV, XRD, BET, laser diffraction, DLS, TGA / DSC, μGC-MS, zeta potential analyzer

- Complex mixtures identification and quantification by GC×GC-HRTOFMS/FID