Specific reactors

In addition to the commercial flow reactors available in-house, Certech also designs custom flow reactors tailored to the specific features of the reaction/process to be developed.

Reactor design requires careful consideration of key parameters, including:

- The chemistry involved and associated kinetics

- The nature of the reaction (homogeneous or heterogeneous)

- The physical properties of the reagents/solvents/products (density, viscosity, solubility, boiling point, etc.)

- The operating conditions (temperature, pressure, residence time)

- The throughput requirements (from a lab-scale proof-of-concept study up to the pilot scale)

Ensuring the safety of operators and equipment (chemical hazards, exotherms, corrosion, etc.) represents another central aspect in our design approach.

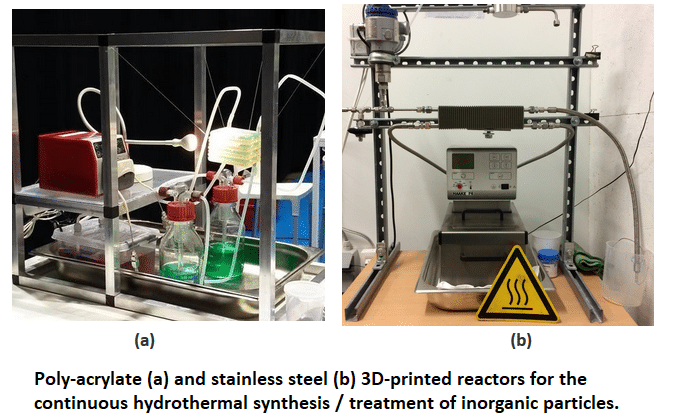

As part of our approach, Computational Fluid Dynamics (CFD) serve as a valuable tool for the rational engineering of flow reactors, enabling the optimization of the reactor geometry to achieve optimal operation conditions (flow pattern, mixing, heat transfer). Complementary to this, 3D printing technology facilitates the rapid prototyping and testing of ideal reactor designs.

Representative examples of custom flow reactors developed at Certech include reactors designed to handle solids (i.e., slurries) in flow, such as for the continuous synthesis of zeolites and MOFs. In another context, we have recently developed flow reactor prototypes for the continuous synthesis of mRNA.