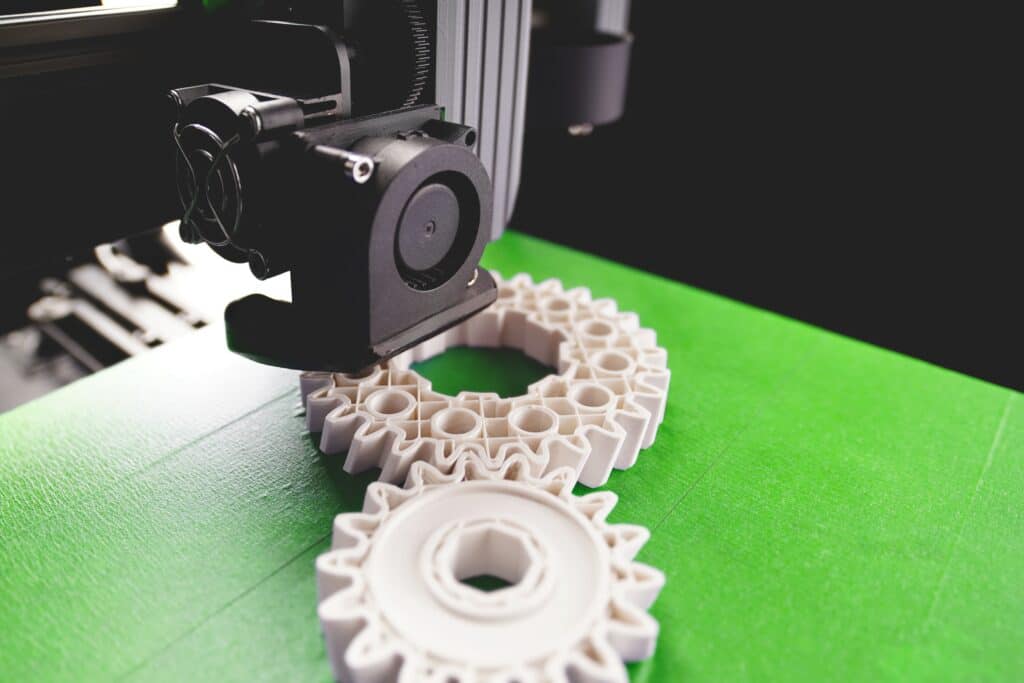

HARDMat project focuses on the formulation of WC-Co/polymer blends for additive manufacturing (AM, also known as 3D printing). Traditional ceramic manufacturing methods have limitations for complex shapes, often requiring additional machining. In comparison, AM technologies enable the creation of more complex parts with precision and generally without additional processing.

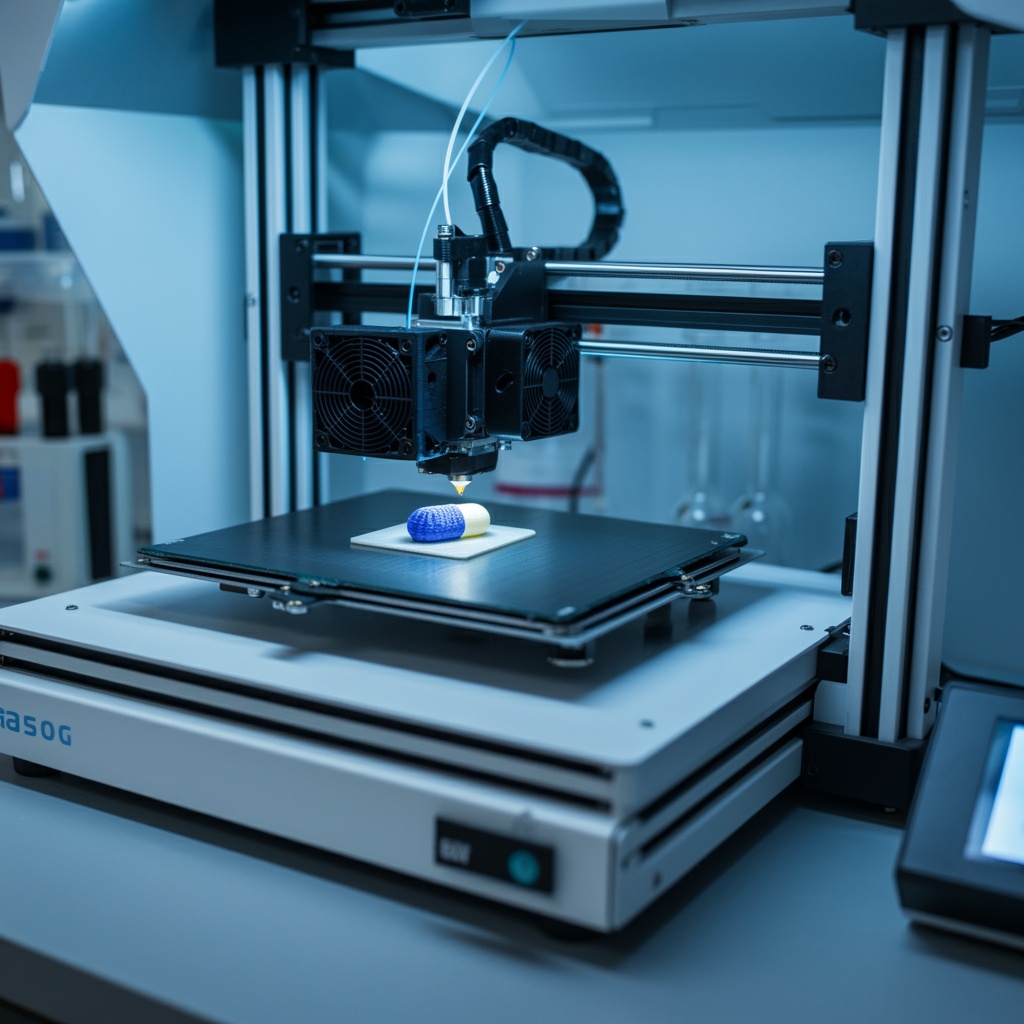

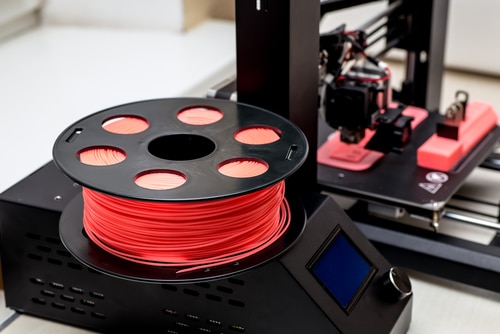

Specifically, metal material extrusion (metal MEX) AM is appreciated for its simplicity and cost-effectiveness. This process includes the preparation of metal powders and polymer binders in a mixture, 3D printing, debinding, and sintering to obtain metal parts.

In HARDMat project, Certech aims to develop new ceramic materials based on tungsten carbide/cobalt by carrying out the following tasks:

• Selecting suitable thermoplastic polymer binders and additives with a low environmental impact.

• Utilizing recycled carbide feeds for mixing with binders.

• Producing granules and powders for AM processes used by the partners.